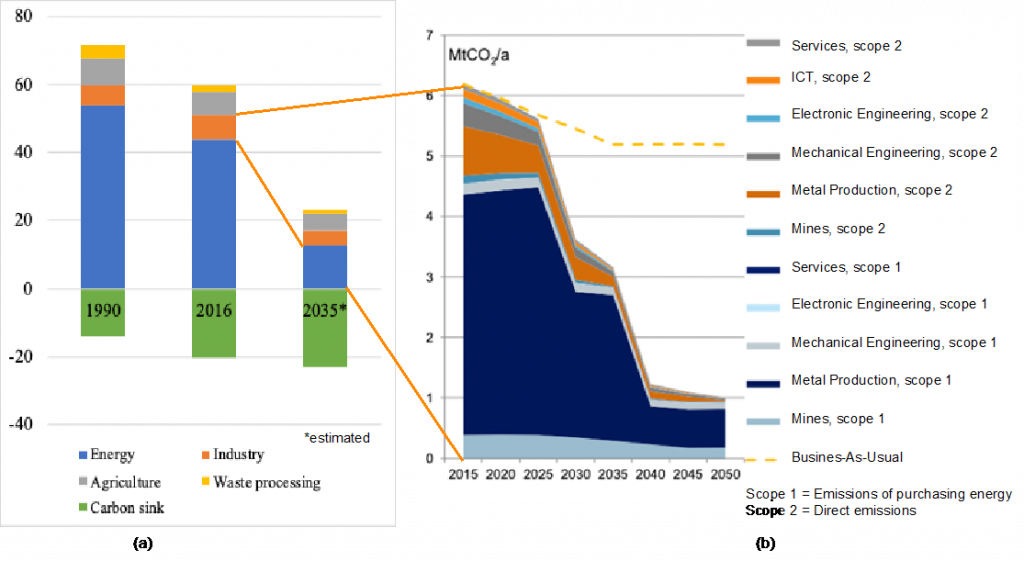

The European steelmaking and mechanical engineering industries have an important role to play in addressing the challenges arising from the new long-term strategy on climate protection, announced by the European Commission in November 2018, and aimed at fulfilling the targets of the UN’s 2015 Paris Agreement. Accordingly, it calls for a climate-neutral Europe by 2050. Insofar as Finland’s contribution to accomplish the climate neutrality is concerned, far-reaching changes and developments in the steel industry will be crucial in accomplishing the challenging targets, as evinced by the exceptional emission targets set for metal production that will strongly dominate the entire Finnish technology industry in immediate future. In this context, Finland’s ambitious aim is to become carbon-neutral already by 2035 and carbon-negative soon thereafter, Fig. 1.

A substantial majority of steel is produced using processes that require carbon, thus resulting in CO2 emissions. Steel industry is responsible for ~7% of annual CO2 emissions globally. A significant part of these emissions stems from the blast furnace process, where iron oxides are reduced with carbon and smelted. Replacing carbon partially or even completely by hydrogen has the potential to drastically reduce CO2 emissions.

Steel is a very innovative material and despite extensive research over decades, only a small fraction of its ideal properties such as strength (» 12.6 GPa) has been utilized, leaving ample scope for future research and innovations. Typical strength-ductility combinations of 1.3 GPa-8% and 2.2 GPa-6% have since been achieved in weldable sheets. However, at laboratory scale, strength-ductility combination beyond 2 GPa-15 % has been achieved in Centre for Advanced Steel Research CASR. Higher strength means less material usage, lightweight products, and reduced emissions in various ways. Based on this concept, it is estimated that the use of advanced ultrahigh-strength steels (UHSS) can decrease total CO2 emission even up to 10 % (worldwide).

Photo by Pixabay (Pexels)