Foam materials can be lightweight, but they can also have good mechanical properties. By using polymer foams, the usage of polymeric material can be reduced, since foams have a lower density compared to the bulk material and so, they require less material. The effect of the chain extenders on the thermal and structural properties (such as density and thickness) of the processed foams were studied in the Thesis.

An alternative for fossil -based plastics

The use of plastics is increasing year by year. Most of the plastics are produced from fossil sources, such as oil. In the future, the availability of these is uncertain or more limited, and alternatives have been researched for decades already.

One alternative is to produce biopolymers, which are biodegradable or/and they are at least partly made of renewable feedstock such as corn or sugar cane.

The properties of polymer foams

Polymer foams are materials that comprise a cellular structure filled with gas. Polymer foams can be produced to be lightweight with good mechanical properties. These properties are needed e.g. in packaging and insulation. For instance, expanded polystyrene (EPS) is a very common example of a polymer foam material used in these purposes.

The weakness of biopolymers during processing

Processing of plastics is performed in increased temperatures, because the polymeric material has to flow during processing. Some of the biopolymers start to thermally degrade in these circumstances, and the polymer chains start breaking to pieces. This leads to decreased mechanical properties of the processed polymer. In the case of polymer foams, the material cannot keep the gas inside, which means that the material will not expand or produce a lightweight foam structure.

There are a couple of solutions to combat the degradation. One of these is using additives that will increase the mechanical properties of the polymer during processing. Chain extenders are additives that can be used for this very purpose.

Chain extenders ease the foam processing

The use of chain extenders is based on their ability to “fix” both the broken and unbroken polymer chains by attaching the chain ends to each other, literally extending them. Also, many chain extenders are compounds that can form bonds with several polymer chain ends, forming more complex chain structures. Crosslinking additives can also be used for the same purpose to connect the chains to each other.

While extending and branching, the tensile properties of the material increase, since the polymer chains cannot move past each other as easily during processing. In foaming, this means that the gas will stay inside the material easier, which allows larger expansion ratios for the foam.

Thesis experiments

In the Thesis, the effect of the chain extenders on the foamability of biopolymers was investigated. Two biopolymers were chosen: poly(butylene succinate-co-butylene adipate) PBSA and poly(3-hydroxybutyrate-co-3-hydroxyvalerate) PHBV.

Two different chain extenders and one crosslinker with multiple concentrations were employed to increase the foamability of these two biopolymers. The foaming was performed with a single-screw extruder, and supercritical CO2 was used as the foaming agent.

The effect of the chain extenders on foaming

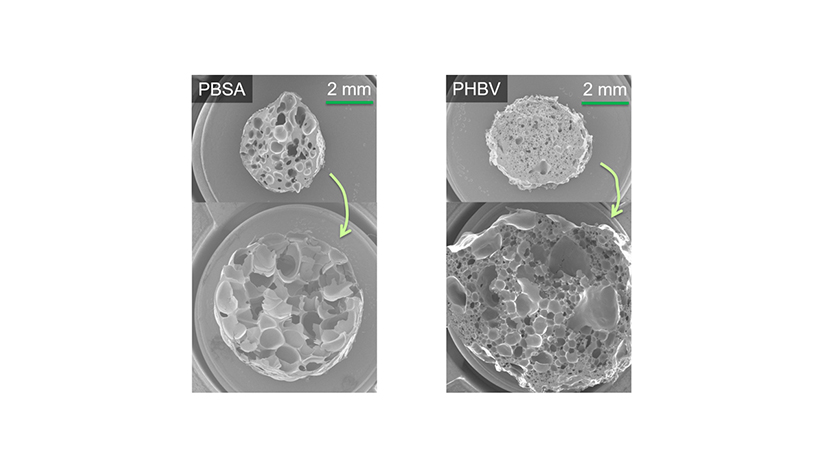

The density of the foams were measured, and they were studied with a scanning electron microscope (SEM) and differential scanning calorimetry (DSC).

In Figure 1, there are SEM images of the cross-sections of the foams. As can be seen from the images, the foams with chain extenders have expanded a lot more compared to the reference foams.

When chain extenders were involved, the densities of the foams were decreased by 50% at most compared to the reference foams. The thermal properties, such as melting point, glass transition temperature and crystallinity did not change much at all when chain extenders were involved.

Finally, it has to be noted that not all the foams expanded as well as seen in Figure 1. Many extrusion parameters have a huge impact on the foam properties in addition to using chain extenders. All in all, chain extenders did have a great effect on biopolymer foamability.

For further information:

Leevi Kurki, leevi.kurki@vtt.fi