The application of wearable devices in the workplace is one of the ways to improve the level of occupational safety. They help to increase safety by monitoring changes in the environment, vital parameters of workers, their proximity to dangerous vehicles, machines, and areas, warn against dangerous situations, enable effective cooperation, optimize processes, and so on. These solutions are especially important in specific work environments such as mining, construction, logistics, boosting the growth of the market of industrial wearable devices.

The benefits of such solutions lie primarily in the increased reliability compared to conventional wearable technology. Often, such wearable devices are designed to work in conditions with an unstable and hazardous environment, for example, high/low levels of temperature, pressure, radiation, and so on. They help to track the readiness of both personnel and worksites for the labor process, cope with consequences of an unstable environment, ensure the efficient distribution of assistance during emergencies and increase the likelihood of success in evacuation operations. For decades, industrial wearable devices have been developed and modified in an attempt to achieve uptime and the ability to provide connectivity to any hard-to-reach worksite (underground, underwater, space). Resilience is a cornerstone of industrial wearable devices since the price of the mistake could be too high.

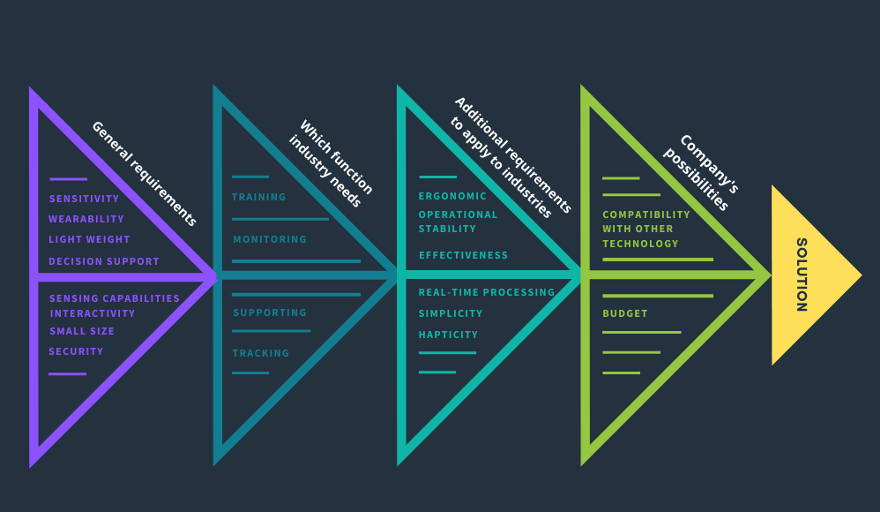

Nevertheless, entrepreneurs are not in a hurry to acquire the innovation due to the different kinds of doubts related to the complexities of implementation, social resistance, insufficient technological features, ethical issues, and uncertainty about the feasibility of costs. However, wearable devices currently available in the public domain could be a cheap alternative. For doing this they should perform one of the basic functions of industrial wearables contributing to the maintenance of work safety level: monitoring, tracking, supporting, or training [1]. Which function is more essential for the particular enterprise depends on industry specifics: manufacturing, metallurgy, construction, warehousing, rail transit and chemical sector, etc. [12]. Let’s review the functions in more detail:

- The monitoring function envisages control of vital parameters of workers or environmental parameters. First gives both, employer and employee, an idea of the readiness of the latter for the work process from a physical, less often psychological, point of view. The second allows an organization to control the overall environmental situation at the factory, prevent emergencies, and provide a worker with proper Personal Protective Equipment (PPE).

- The tracking function deals with the identification of the worker’s location to prevent collision with equipment and unauthorized access to hazardous work areas and machinery, to plan evacuations in the most efficient way, and to wisely distribute help and work forces.

- Simplification of information management and communication between workers, increasing their physical capabilities represent supporting functions of industrial wearable devices. The typical examples are exoskeletons, patches, which control the position of the body when lifting heavy objects, and wearable robots.

- Through training function, wearables provide information about how well a worker performs the task in terms of quality, time, posture correctness, and also ergonomy. Thus, the worker can track his activity and avoid dangerous movements. Using Virtual Reality (VR) and Augmented Reality (AR) helmets, it is possible to teach workers how to perform complex tasks before doing them in reality, thereby reducing the likelihood of injury.

The importance of monitoring and tracking wearables has significantly increased during the Covid-19 pandemic: first helps to track the virus symptoms and second allows to preserve social distance and timely isolate people who were in close contact with an infected person [2]. However, even before pandemics, these industrial wearables were the most common among all the others and, despite sometimes enterprise realities requiring some specific metrics or high accuracy, in other cases, many public domain wearables could be used as an alternative.

On the other hand, wearables, which main functions are supporting or training, are less common and usually quite expensive due to specificity. Fortunately, the majority of industries do not require such equipment.

The main design recommendations for wearable devices from the public domain that are going to be used as industrial devices are reliability and simplicity. First envisages long battery life, industrial protection to work in extreme environments, and network connection stability. Second, simplicity means that at the same cost, the simpler the mechanism, the easier the device is to operate and the less likely it is to fail. Fortunately, both recommendations are needed and desired by the enterprises because it means spending less budget on work safety purposes without buying expensive specialized equipment.

Additionally, we should mention design recommendations, which are considered mostly common to all wearable devices and are critical when it comes to the industrial environment [3], [4]:

- wearability/ergonomy – the device should be low-weight, small-size and shouldn’t constrain movements.

- interactivity – for the sake of cognitive freedom, the wearable interface should be intuitive and simple. Voice interaction is preferable to ensure quick communication without distraction from the work process.

- security – it should not be forgotten that the private data should be protected.

- real-time processing – for the industrial scenario, it is highly needed that the measurements will be processed in real-time to timely react to any change in the work environment.

- decision support system – the additional algorithms could help to make a decision as quickly and correctly as possible, decreasing the probability of human-related mistakes.

Such widely available wearables as fitness trackers, smart rings, smart glasses, and smart clothing could be used for performing monitoring functions, measuring the most important parameters related to the human body: temperature, heart rate, and perspiration. Smart bracelets, smart clothes, smart boots, digital pedometers will be capable of ensuring the positioning of workers in outdoor worksites (e.g. agriculture, construction) or not in a very noisy indoor environment (e.g. warehouses) with accuracy acceptable to identify the presence of the worker in the particular place in case of an accident. Moreover, there are also devices capable of performing both functions at once: a wide range of fitness trackers [5] and smartwatches with GPS [5], [6] or smart rings with NFC (Near Field Communication) [7]. Regarding the controlling of environmental impact, a more profitable solution would be not wearables but wireless networks that will include sensors, monitoring required parameters: light [9], noise [10], air composition [11], [12], and so on. Figure 1 schematically shows the process of choice of wearable solution from the public domain to ensure workplace safety in the enterprise.

Fig. 1. Graphical interpretation of work safety through wearables available in public domain.

To conclude, in the enterprises, which are working in hazardous environments, occupational safety could be increased by the wearable devices widely available in the public domain. Such devices as usual smartwatches and fitness trackers will provide monitoring of the most important parameters of the workers (heart rate, location, etc.), embedded proximity sensors will allow to decrease the probability of collision in the workplace and to keep social distance, finally, easy-to-purchase and to implement environmental sensors will cope with the monitoring of changes in surroundings. Moreover, publicly available and relatively cheap wearables could become the important first trial stage before acquiring expensive complex wearable solutions for enterprises: it will give an understanding of how it works and reduce the degree of social resistance that would be an essential step towards the adoption of industrial wearable technology. The only way to eat an elephant is one bite at a time.

by Ekaterina Svertoka, Justyna Skibińska

References

- Svertoka E, Saafi S, Rusu-Casandra A, Burget R, Marghescu I, Hosek J, Ometov A. Wearables for Industrial Work Safety: A Survey. Sensors. 2021; 21(11):3844. https://doi.org/10.3390/s21113844

- Estimote. Workplace Safety with Wearables. Available online: https://estimote.com/wearable/

- Meng, Y., Choi, H. K., & Kim, H. C. (2011, June). Exploring the user requirements for wearable healthcare systems. In 2011 IEEE 13th International Conference on e-Health Networking, Applications and Services (pp. 74-77). IEEE.

- Genaro Motti, V., & Caine, K. (2015, September). An overview of wearable applications for healthcare: requirements and challenges. In Adjunct Proceedings of the 2015 ACM international joint conference on pervasive and ubiquitous computing and proceedings of the 2015 ACM international symposium on wearable computers (pp. 635-641).

- Best Smartwatches and Fitness Trackers with GPS 2021. Androidcentral. Available online: https://www.androidcentral.com/best-smartwatches-and-fitness-trackers-gps

- Auepanwiriyakul, Chaiyawan, et al. “Accuracy and Acceptability of Wearable Motion Tracking for Inpatient Monitoring Using Smartwatches.” Sensors 20.24 (2020): 7313.

- Gheran, Bogdan-Florin, and Radu-Daniel Vatavu. “From controls on the steering wheel to controls on the finger: using smart rings for in-vehicle interactions.” Companion Publication of the 2020 ACM Designing Interactive Systems Conference. 2020.

- COMPARE THE SIX MOST POPULAR NFC SMART RINGS. Smart rings news. Available online: https://www.smartringnews.com/compare-the-six-most-popular-nfc-enabled-rings

- Texas Instruments. OPT3006 Ultra-Thin Ambient Light Sensor. Available online: https://www.ti.com/product/OPT3006

- Smart Sensor AS834+ Industrial Noise Meter Sound Level Meter Decibel Detector. Amazon. Available online: https://www.amazon.com/Smart-Sensor-Industrial-Decibel-Detector/dp/B07YG1B7N5

- CO2 sensors. Infineon. Available online: https://www.infineon.com/cms/en/product/sensor/co2-sensors

- Nitrogen Dioxide- NO2 Sensors. Spec Sensors. Available online: https://www.spec-sensors.com/product-category/gases/nitrogen-dioxide-no2-sensors/