We are excited to announce that Ninja Kajas has published their first research article in the impactful journal Flexible and Printed Electronics (IOP Publishing): https://iopscience.iop.org/article/10.1088/2058-8585/aded20/meta

Their paper presents an innovative all-solution-processed method to create an ultra-thin, flexible piezoelectric sensor on a polyimide substrate. This sensor, designed for applications like wearable devices and electronic skin (e-skin), uses inkjet-printed electrodes and a carefully optimized active layer to achieve high sensitivity and flexibility—key features for next-generation healthcare and soft robotics technologies.

With a total thickness under 1 micron and strong piezoelectric performance, this research contributes important advances toward low-power, flexible electronics that can mimic the human skin’s sensing abilities.

We’re proud to see our student’s hard work recognized in a leading journal and look forward to their future contributions in flexible electronics and smart materials.

Abstract:

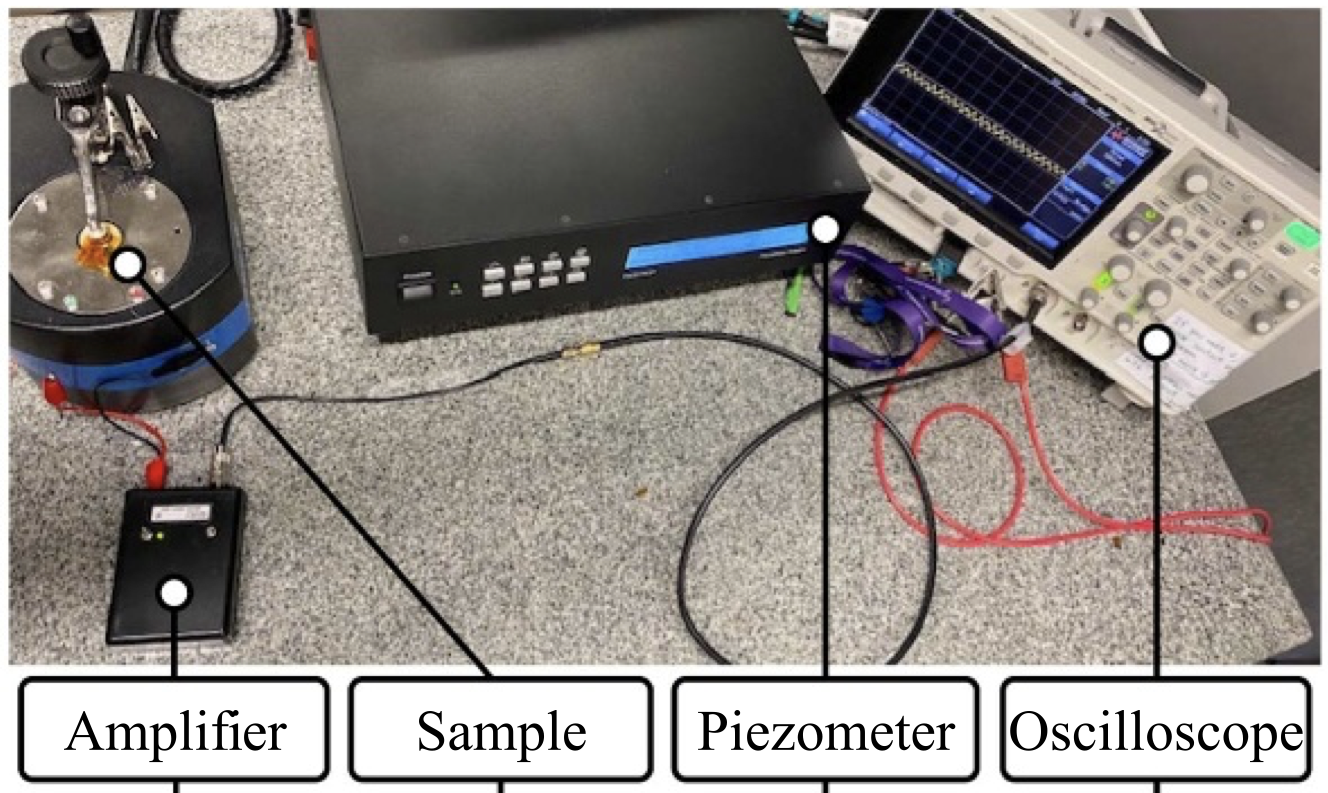

The development of flexible electronics is essential for advancing technologies like wearables, environmental sensors, and electronic skin (e-skin), which are used in applications ranging from healthcare to soft robotics. E-skin, inspired by the human skin’s sensory capabilities, requires flexible and conformable materials to mimic the dynamic responses to shear, pressure, temperature, and pain. Traditional rigid electronics fabrication methods, which require high processing temperatures, are unsuitable for flexible substrates. Additionally, the requirement for low-power and energy-autonomous devices present challenges that could be addressed with piezoelectric materials. In this study, we present an all-solution processed method to fabricate an ultra-thin, piezoelectric sensor on a flexible polyimide substrate. The sensor’s electrodes are inkjet-printed using poly(3,4-ethylenedioxythiophene) polystyrene sulfonate, while the active layer of poly(vinylidene fluoride-co-trifluoroethylene) is formed by spin coating. The fabrication process is optimized by varying annealing temperatures and using two casting solvents while spin coating, methyl ethyl ketone and dimethyl sulfoxide, to assess their impact on the active layer performance. The resulting sensor has a sandwiched structure with a final thickness of less than 1 µm, including a 289 nm thick active layer. The sensor demonstrates a remanent polarization of 7.9 µC cm−2 and a piezoelectric coefficient d33 of 12.4 pC N−1.