In BeLight project bio-based alternatives for traditional fossil-based foams will be studied and developed. BeLight bio-based polymer foams answer to this challenge with the following advantages:

- Independence from non-renewable fossil raw materials

- Reduced material consumption

- Light-weight products with good mechanical properties

- In some cases biodegradability at end-of-life stage

Polymer foams

Polymer foaming is a process where gas filled cells, bubbles, are introduced to the material structure. With foaming, density of a material can be reduced as less material is consumed. In addition, density of the foam can be controlled and a broad range of densities can be produced based on the product requirements. This results in reduction of weight and material costs. These properties make polymer foams attractive for light structures such as flotation, automotive parts and packaging.

Polymer foams typically have low thermal conductivity, which also makes them ideal for insulation purposes. Polymer foams can also have varying ranges of stiffness and therefore they can be used in comfortable cushioning or in stiff structures. Generally, foams have low strength but high toughness, which makes them useful in energy absorbing application.

The most commonly used petroleum based polymeric materials in foam applications are polystyrene PS and polyurethane PU. These are both fossil-based polymer foams and therefore non-renewable. Unfortunately, recycling of these PS and PU polymer foams is also challenging, uneconomical and their degradation in nature is slow.

Basics of thermoplastic polymer foams

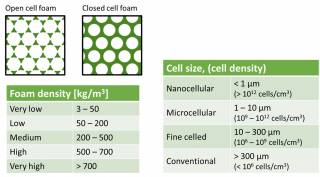

It is possible to produce both open cell foams and closed cell foams. Closed-cell foams are generally more rigid, while open-cell foams are usually flexible. In BeLight biopolymer foams we concentrate on closed cell foams.

Classification of thermoplastic foams:

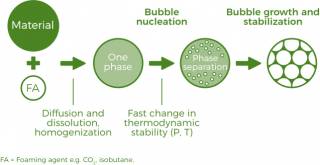

There are two different technologies used for producing bio-based polymer foams in BeLight: extrusion foaming and particle foaming. The principle of the thermoplastic foaming phenomena is presented below:

Extrusion foaming

The generation of cell structure in extrusion foaming proceeds in following steps:

- Nucleation

- Bubble growth

- Bubble stabilization, solidification of foamed structure under cooling

The following parameters affect the cell size and morphology:

- Temperature

- Die size and pressure drop rate at die

- Diffusion of physical foaming agent into polymer matrix

- Polymer employed in extrusion

Particle foaming

In particle foaming, products are created from fused beads that expand in a heated mould. The beads, or particles, consist of small closed cells, creating a foam structure.

Thermoplastic foaming possibilities at VTT

Studying and developing thermoplastic materials in extrusion foaming process in VTT’s laboratory scale equipment or bigger Tandem extrusion foaming line is possible in material range from 2 kg to 100 kg. The use of chemical or physical foaming agents is possible.

Beads for particle foams are produced using twin-screw extruder with foaming agent injection and high pressure underwater micropelletizer. The samples are produced by hot steam moulding.

Laboratory scale Single Screw Extrusion Foaming Line

The foaming properties of thermoplastic materials, optimal foaming parameteres and needed additives as well as suitable foaming agents can be studied with VTT’s laboratory scale extrusion foaming line. The line is suitable for small material quantities of about 2 kg.

Equipment:

- Manufacturer Brabender®

- 19 mm extruder (L/D 25)

- Blowing agent injection with Teledyne ISCO syringe pump

- Static mixer

- Melt pump

- Melt cooler

- Tube die, flat die, capillary dies with different L/D ratios

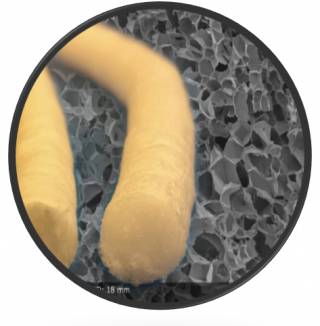

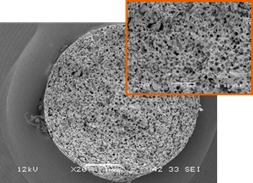

Picture of VTT’s laboratory scale extrusion foaming line and SEM image showing cross-cutted foamed polymer sample (x20 and x 50).

Pilot Scale Tandem Extrusion Foaming Line

Pilot Scale Tandem Extrusion Foaming Line is for production of foamed sheet or board for further characterization e.g. thermal insulation, compression strength etc. The thermoplastic material need for the trials is 50 – 100 kg.

Equipment:

- 35 mm main extruder

- 75 mm cooling extruder

- 18 mm sealing extruder

- Gravimetric feeders for two additives

- Different die geometries

- Throughput 5 – 30 kg/h

- Calibration unit for board

Expandable or expanded particle foams

The production of micro-pellets/particles with the foaming agent is performed in Krauss-Maffei twin-screw extruder Ze25A x 49D UTX equipped with high pressure under water micro-pelletizing unit (Gala) pelletizing system and direct blowing agent injection. Pre-expander and moulding machine will be delivered to VTT during 2020.